Part 2 Heavy Duty Variable Speed Ball Mill from Treadmill

Nov 13, 2014#0183;#32;A final video of the build of my variable speed ball mill... Side note More GUNS and BEER videos after deer season, happy hunting everyone....

WhatsApp)

WhatsApp)

Nov 13, 2014#0183;#32;A final video of the build of my variable speed ball mill... Side note More GUNS and BEER videos after deer season, happy hunting everyone....

Mar 31, 2018#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

How to Make a Metal Lathe Knob Turner: This is my finished ball and knob turner. You can make knobs out of any material you want . Brass,plastic,aluminum,steel, wood .This style of turner i can create a ball up to 1 1/4 inch round.

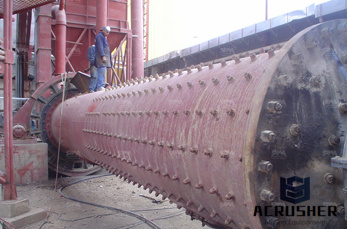

How Ball Mill Works,Ball Mill Working principle,Ball Mill Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype

Feb 09, 2008#0183;#32;This guide will teach you how to make your very own Aluminum Powder! Home Latest Popular Trending Categories. Art Animation of #1 2 german dark own make learning part flash aluminum your indians powder

Jul 25, 2008#0183;#32;Visit:

Ball mills, along with grinding mills, impact crushers and a variety of other equipment, are used for the reduction of all kinds of materials for all kinds of purposes. Size reduction is an important part of many industrial processes, making ball mills and other pulverizing mechanisms vital

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Dec 16, 2017#0183;#32;Clay Ball Mill Part 1 Fundamentally. Loading... Unsubscribe from Fundamentally? Cancel Unsubscribe. In this video, I work on building a ball mill for crushing up clay. I

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

Sep 10, 2014#0183;#32;Drill plunging axially on left, endmill cutting laterally on right. Heres the key difference. Drill bits are designed to plunge directly into material, cutting axially and creating cylindrical holes. End mills are typically used for horizontal carving and cut laterally. Additionally, most mills are centercutting, meaning they are able to cut both axially and laterally.

Apr 07, 2011#0183;#32;To make a ball mill, start by building a wooden platform and attaching a motor underneath it. Then, cut a slit into the wooden platform for the belt to pass through and attach casters to the platform for the container to sit on. Next, thread the belt through the slit and position the container so the belt is pulled tight.

Nov 26, 2014#0183;#32;DIY homemade ball mill. Easy to make Made from some PVC pipe, a few castors, and electric motor, and a power supply

Jul 08, 2014#0183;#32;I found a reasonable 18mm Ball End Mill on Amazon. Edit: Updated to 4flute which should help bit chattering with previous 2flute version. Link goes to the search results since they seem to go inandout of stock quickly. 18mm Ball End Mill 4Flute (~70) 3/32 x 3/8 Key Seat Cutter: I went with this Whitney 3/32 x 3/8 Key Seat Cutter (17

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified feature, such as a profile, slot, pocket, or even a complex surface depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

The mill speed, ball to powder ratio,... influence is clear. I just wanted to learn the basics of this type of calculation for each type of matter. I am looking for the best source of study.

Pyrosecrets Learn How To Make A Ball Mill At Home . Pyrosecrets learn how to make a ball mill at home a ball millwhich is a type of crusheris a cylindrical device used to grind chemicals into a very fine powder to increase the surface area of pyrotechnic compositions and make the reactons take place fasterblack powder and other flammable materials require nonsparking lead antimonybrassor

Take your newly shredded aluminum grains and pour it into your ball mill. Optional step to improve quality: Dump in two scoops of charcoal powder for every cup of aluminum. This will increase the burn rate and make german dark aluminum powder. With your aluminum shreds in the ball mill, add 1530 marbles until the ball mill is 3/4 full.

Nov 12, 2017#0183;#32;Making a ball mill from a fire extinguisher and an office fan Duration: 11:06. Part 2 Heavy Duty Variable Speed Ball Mill from Treadmill Parts Duration: 5:57.

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding

Aug 04, 2008#0183;#32;English In this video we''ll learn how to make a ball mill. For this part we need.... A washing machine mo... English In this video we''ll learn how to make a ball mill. For this part we need.... A washing machine motor. The respective cables of the motor. Plier and electrical tape. For connecting the motor to the power socket we have to

Jan 20, 2010#0183;#32;A ball mill I made of a Scitec Nutrition HDPE can, and a motor obtained from an old bread machine. This is the first run, without any load. An old transformer is used to make 140 V AC, this way

Ball Mill Working Principle And Main Parts. Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

WhatsApp)

WhatsApp)